Water originates from various sources and can vary significantly in quality. Makeup water contains invisible dissolved minerals and insoluble matter that can impact cooling efficiency and equipment service life. These substances include dirt, minerals, gases, and microbiological organisms that, if not properly treated, can accumulate and cause reductions in heat transfer efficiency, equipment service life or increased maintenance requirements.

As heat is rejected, the water evaporates as pure H2O leaving all the dissolved minerals behind to concentrate in the basin. As fresh water is added to replace evaporated water the dissolved minerals increase, a concept known as Cycles of Concentration (COC) or Cycling Up. The quality of the makeup water directly influences how high the cycles can safely be pushed which directly impacts water efficiency.

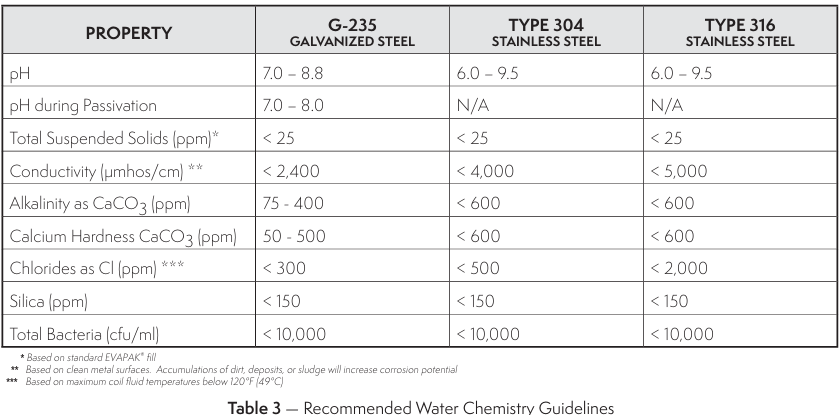

The quality of makeup water also plays a role in selecting appropriate materials of construction for your evaporative cooling equipment. Different materials have varying levels of corrosion and temperature resistance. Poor makeup water quality may necessitate the use of more corrosion resistant materials, such as 304 or 316 stainless steels. To aid in materials of construction selection, EVAPCO® has published water quality guidelines for open cooling towers, closed circuit coolers, and evaporative condensers that can be reviewed when making decisions on materials of construction:

Ultimately, understanding your makeup water quality will not only allow you to run your evaporative cooled system more efficiently by optimizing your cycles of concentration, but can also help extend your equipment’s service life by selecting appropriate materials of construction.

For more information, please contact your EVAPCO® Sales representative or [email protected].